The customer supplied camshafts for a Lotus TC engine we are currently building had previously been modified by removal of the single large diameter OEM cam sprocket locating dowel, filling of the dowel hole and then the camshaft flanges were drilled with 15 smaller diameter holes. The engine was supplied to us piecemeal and partially complete. As such, the suitably modified camshaft sprockets that would have been used with the modified camshafts were not supplied to us.

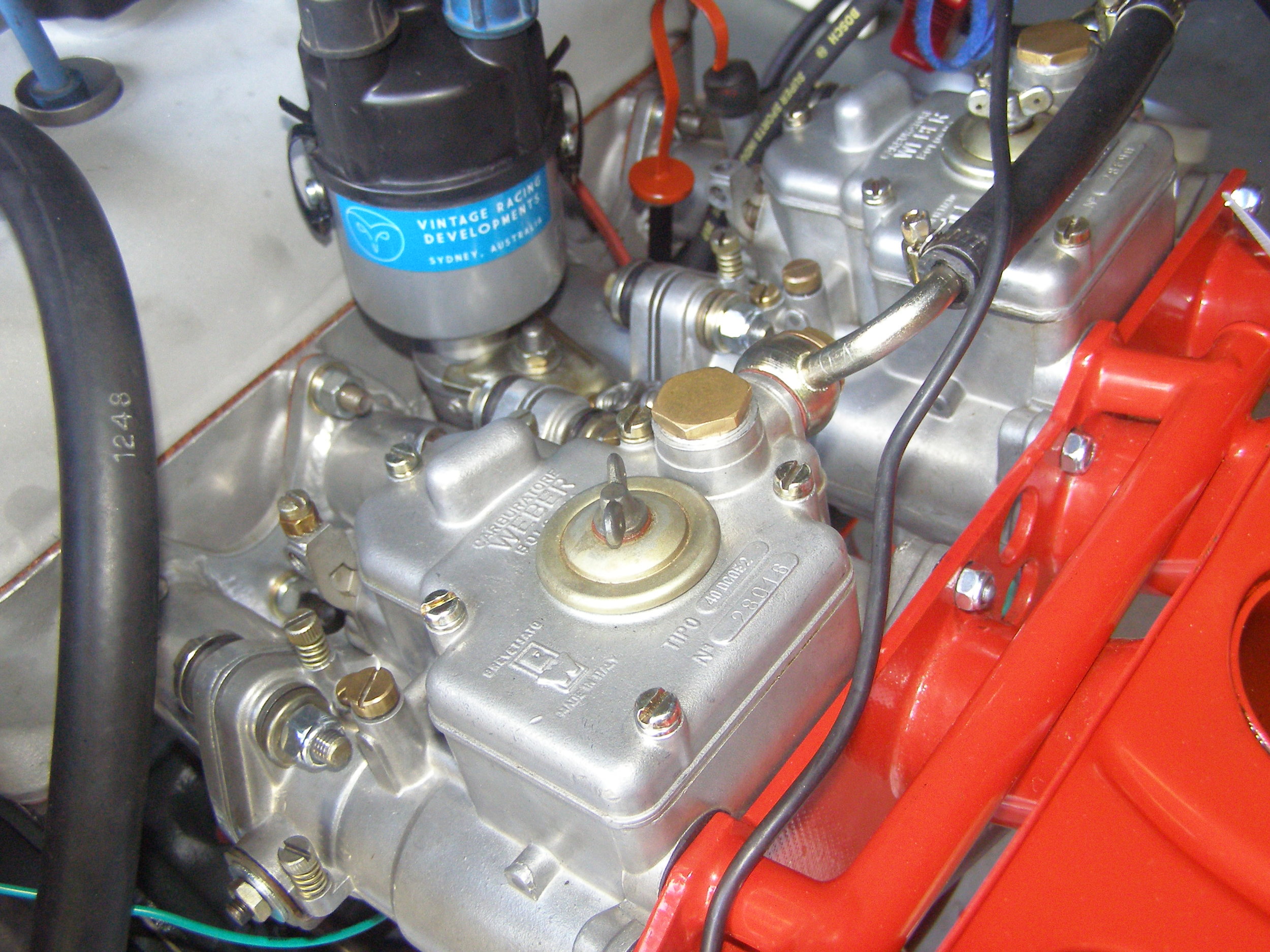

As a result, we synthesised and calculated the required companion vernier holes required in the camshaft sprockets (16 if full circumference) and modified two standard sprockets accordingly. An interesting little exercise.

We ended up having the camshafts freshly reground and during mock build with light checking springs to degree the cams in to specification & assess valve to piston and valve to valve clearance, the IN and EX sprockets were marked at the exact relative index locations required for their respective companion camshaft. The centre vernier hole in each sprocket is the pre-determined master index hole for each camshaft, with the holes either side allowing fine final adjustment when the engine is assembled with the actual valve springs to be used that of course deliver far more force than the light mock build checking springs. As due to prior mock assembly only very fine adjustment if any may be required at final engine assembly, the full circumference set of 16 vernier holes in the sprockets are not required.

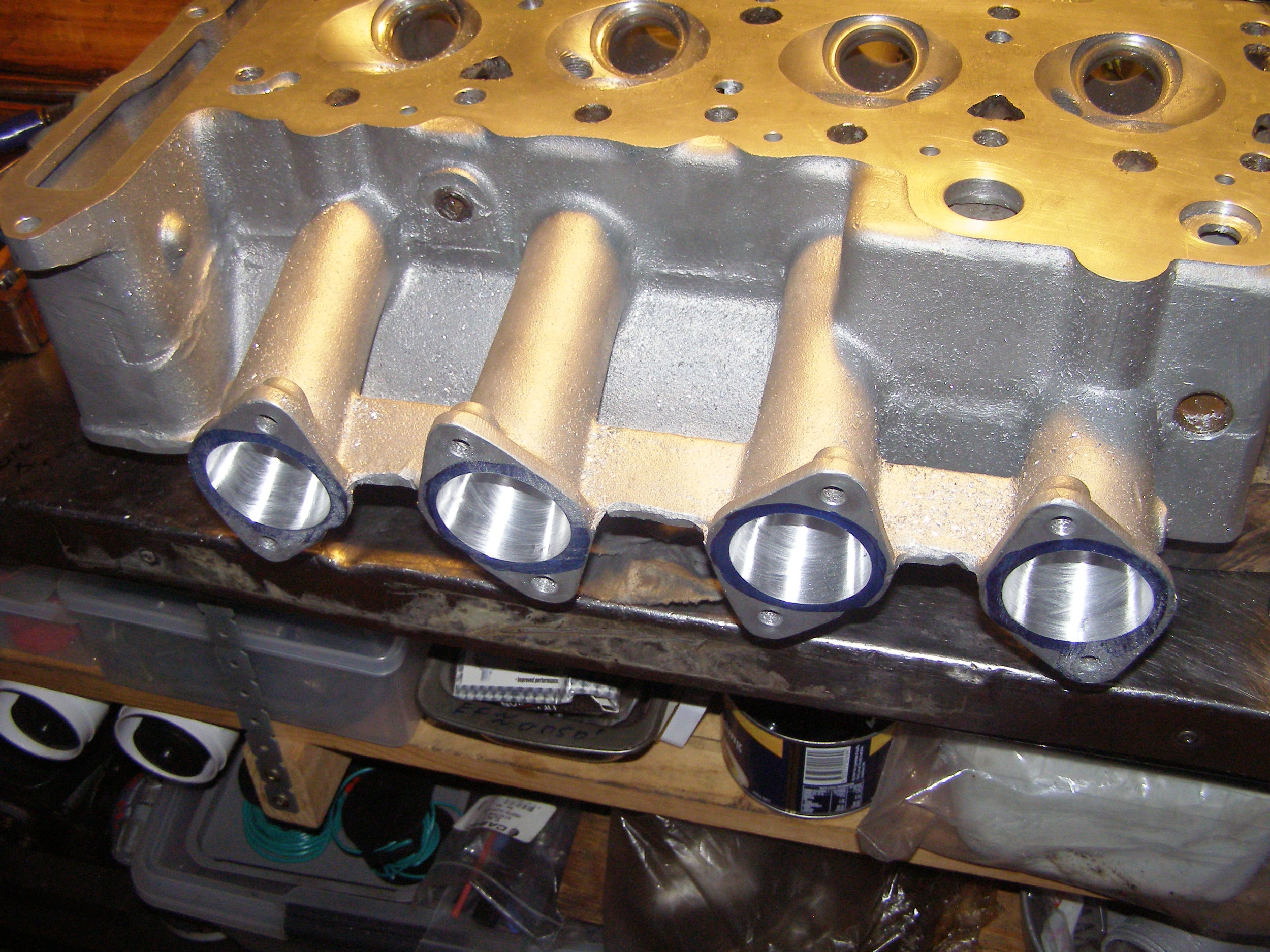

Standard Lotus TC Camshaft Flanges from one of our earlier builds

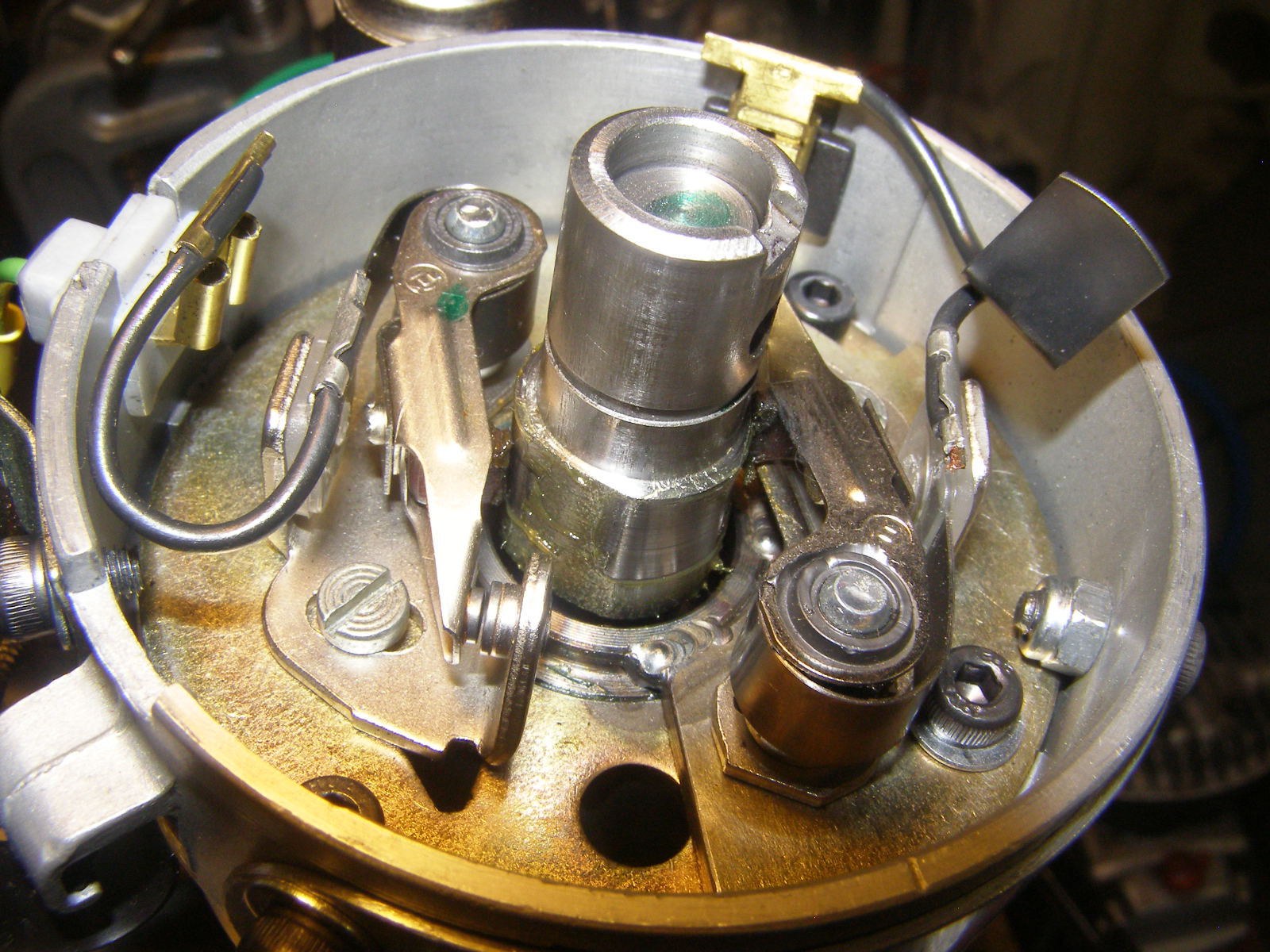

Camshaft with pre-existing previously applied multiple vernier holes (note filled original dowel hole)

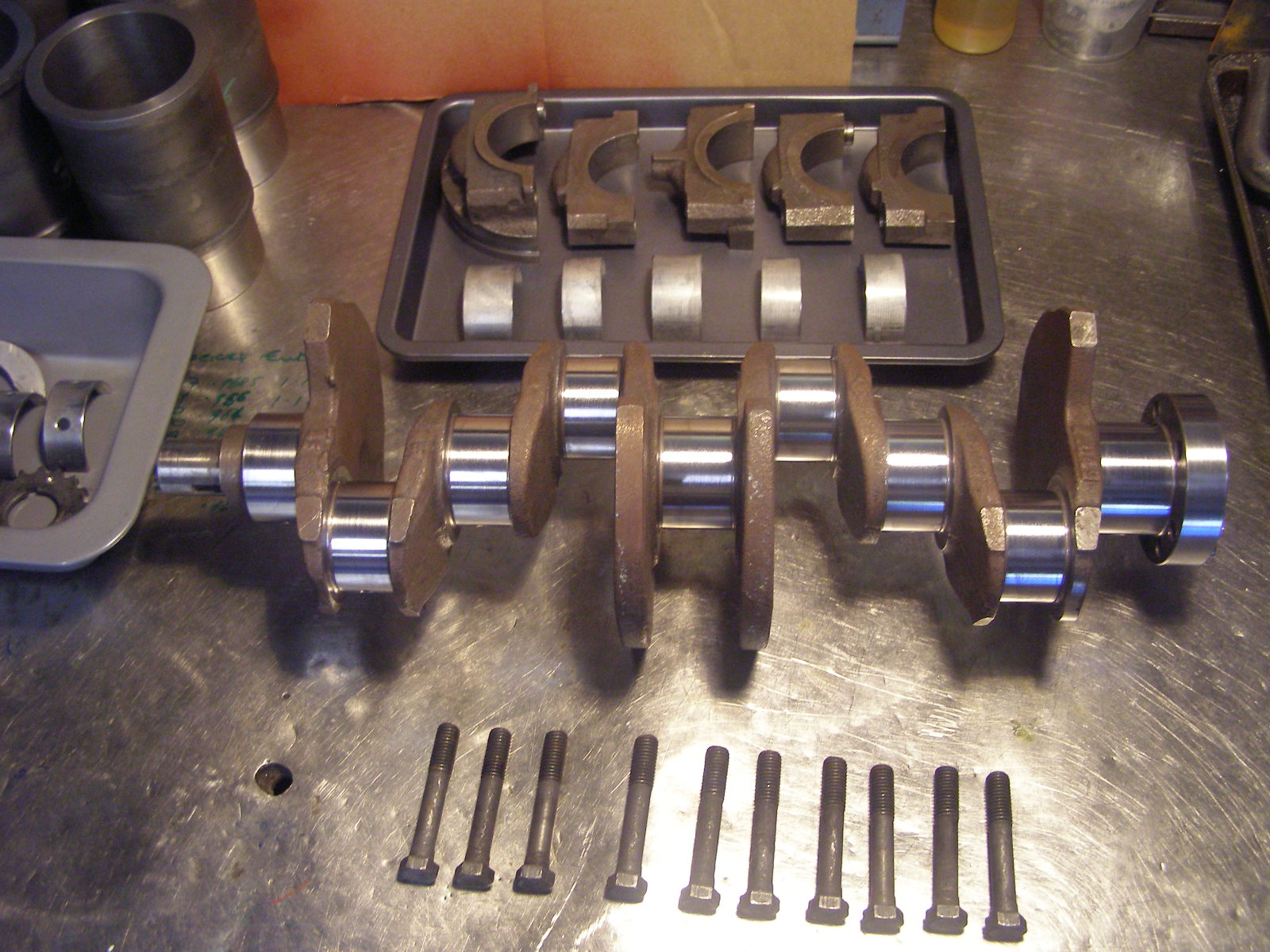

Locating hole PCD and circumferential index with fixture in indexing head/rotary table on mill bed

Finished modified sprockets showing small vernier holes and larger OEM holes

![IMG_20160628_225452[1].jpg](https://images.squarespace-cdn.com/content/v1/55507930e4b0e94d5db9d87f/1467593687721-NHAKPYM5D1KCME7XVKSO/IMG_20160628_225452%5B1%5D.jpg)